- MenuBack

-

Home

Home - Solutions

- Anticorrosion, metal structures and objectsAnticorrosion, metal structures and objects

- Concrete, walls and exterior facadesConcrete, walls and exterior facades

- Roofs & WaterproofingRoofs & Waterproofing

- Balconies and terracesBalconies and terraces

- Floors: garages, warehouses, technical rooms, parkingsFloors: garages, warehouses, technical rooms, parkings

- Products

- References

- RD Coatings Academy

- Our company

- News

- Contact

RD-Monoguard, a new landmark in anti-corrosion protection.

Since the launch onto the world market 5 years ago, RD-Monoguard is proving that it is a perfect choice for the long-term anti-corrosion protection for steel structures located in harsh environments.

This is being confirmed by a growing number of contractors, project managers and owners, who are now using RD-Monoguard for the long term preservation of their assets made of steel and other non-ferrous metals.

Amazing adhesion values

One of the main properties of RD-Monoguard which is actively contributing to the anti-corrosion protection of steel, is its very high adhesion values to a wide variety of surfaces.

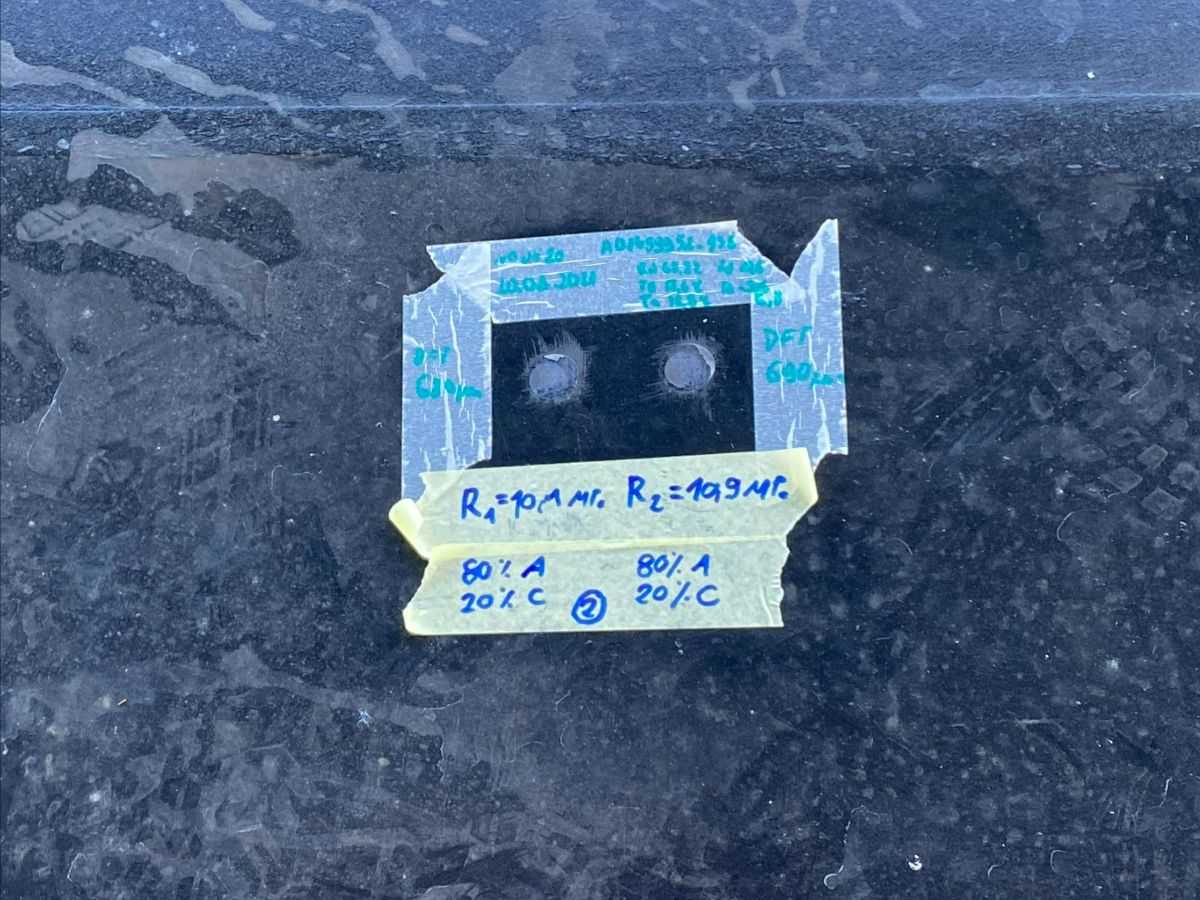

Testing has proven that the measured adhesion values increase over time. Measurements taken weeks and months after the application prove that the very innovative formulation of RD-Monoguard reaches levels as high as 17 Mpa / 2500 PSI when doing a pull off test following ISO 4624. These are values far above the 7 Mpa / 1000 PSI regularly required by many industrial specifications.

Why is the adherence so important?

There has been a direct correlation between the high adhesion of coatings to increased anti-corrosion protection. In short, the high adhesion of RD-Monoguard (which has literally fused with the metal substrate) helps block the formation of corrosion on the steel surface and also prevents the formation of rust creep whenever the coating is physically damaged or scratched.

ISO 12944 – approval for C5 HIGH

The Dutch accredited laboratory COT, internationally recognized for testing anti-corrosion coatings, formally recognized RD-Monoguard’s superior performances by testing it following the ISO 12944 norm.

RD-Monoguard can protect steel for more than 15 years – HIGH – in marine and industrial environments – C5, confirming once more our many in-house and field results.

Comparison with other coatings for equivalent performance

| RD-Monoguard SCS system | Competing epoxy/pur system |

Primer coat | 100 / 4 | 60 / 2,4 |

Second coat | 100 / 4 | 120 / 4,8 |

Third coat |

| 80 / 3,2 |

Total | 200 / 8 | 260 / 10,4 |

With only two coats and 200 µ / 8 mils dry

While traditional solvent-based epoxy/polyurethane systems need 3 coats of 3 different products – meaning 8 to 9 different products to handle, if you include the hardeners and thinners - to achieve the same results, RD-Monoguard is single-component and water-based, has no pot-life, is ready-for-use, UV resistant and safe to apply, in just two coats!

SCS – Single Coating System by RD Coatings

RD-Monoguard is our new ambassador among our list of SCS products which stands for:

ONE PRODUCT – TWO COATS – JOB DONE!

Application of RD-Monoguard versus traditional coatings

| RD-Monoguard SCS system |

1/ Surface preparation | · Sand blasting is optional · Preferred surface preparation: High Pressure Washing |

2/ First coat | Apply directly RD-Monoguard. |

3/ Second coat | Apply RD-Monoguard. |

4/ Third coat | You are already busy with your next job! |

| Competing epoxy/pur system |

1/ Surface preparation | Sand blasting always required with zinc rich coatings and most traditional protective coating systems |

2/ First coat | Mix, thin and apply primer coat. Beware of pot life and mixing mistakes! |

3/ Second coat | Mix, thin and apply intermediate coat. Beware of pot life and mixing mistakes! |

4/ Third coat | Mix, thin and apply top coat. Beware of pot life and mixing mistakes! |

Higher project productivity

The very fast dry times along with its dry fall properties allows the spray application of the two-coat system within the same day! RD-Monoguard has no overcoating window, in other words, any interruption in the job can be resumed any day, week, month or years later. Therefore, any repair that has to be made in the future is also very simple.

And the product is ready-for-use, which maximizes the productivity of the workers.

A very simple system that enormously reduces any risk of mistakes.

And so much more …

RD-Monoguard SCS system offers so many advantages to all stakeholders when compared to traditional solvent-based systems.

Don’t wait any longer, contact your closest RD Coatings representative to organize a trial.